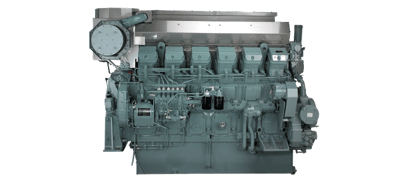

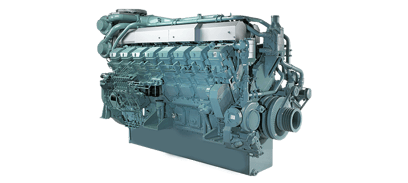

Dedicated to meet your power generation needs.

As part of Mitsubishi Heavy Industries Group, we share its global commitment to using technology and engineering to be a leading producer of quality engine & generator set products.

Mitsubishi partners

MTEE appoints Diamond Industrials Services (DIS) as a dealer in Greece

We welcome DIS as our official dealer of Mitsubishi Turbocharger and Engine Europe B.V. (MTEE). DIS is now responsible for the sales and...

Mitsubishi partners

MTEE appoints Diamond Industrials Services (DIS) as a dealer in Greece

We welcome DIS as our official dealer of Mitsubishi Turbocharger and Engine Europe B.V. (MTEE). DIS is now responsible for the sales and...

Hybrid

How smart hybrid power can electrify the remotest parts of the planet

Access to a reliable electricity supply can transform the lives of people with no mains power. This smart triple-hybrid system can help...

Hybrid

How smart hybrid power can electrify the remotest parts of the planet

Access to a reliable electricity supply can transform the lives of people with no mains power. This smart triple-hybrid system can help...

Hydrogen

How hydrogen can get Europe’s inland waterways to net zero

Inland shipping is vital for trade and logistics in Europe and is more CO₂-efficient than road or rail. Although there are still efforts...

Hydrogen

How hydrogen can get Europe’s inland waterways to net zero

Inland shipping is vital for trade and logistics in Europe and is more CO₂-efficient than road or rail. Although there are still efforts...

As part of Mitsubishi Heavy Industries Group, we share its global commitment to using technology and engineering to be a leading producer of quality engine & generator set products.

Let us know your question or inquiry and an expert will get back to you shortly.